Violin-playing robots may attract millions of views on YouTube, but those that are really changing the world are the ones designed to perform mundane tasks with a high degree of precision while keeping their human co-workers safe.

Building the sorts of robots that can work in close proximity with people has only come about in recent years thanks to greater computing power and ever smaller sensors and motors. It's become a specialised field concentrated in industrial clusters like Odense, a former shipbuilding centre in Denmark, which members of the Pictet-Robotics Advisory Board recently visited.

During the 1980s when Danish shipyards were struggling with cheaper competition from rivals in places like South Korea, far-sighted owners started to look for ways to automate some of the skilled but in particular mundane jobs like routine welding. A large grant to the local branch of the Danish Technological Institute helped seed what has since become a significant centre for robotics. Today, there are 4,000 people working on robotics in Odense, making Denmark one of the major robotics countries in the world.

With the focus squarely on commercial applications, the work done by Odense robotics companies is less glamourous than, say, the humanoid machines developed by boffins at MIT. But the technology is no less complex or impressive - like the collaborative machines produced by Universal Robots, an Odense company owned by Teradyne.*

For instance, assembly-line robots may have long been an industrial staple, but those that work autonomously yet closely in tandem with people are only just beginning to take off, according to the Advisory Board.

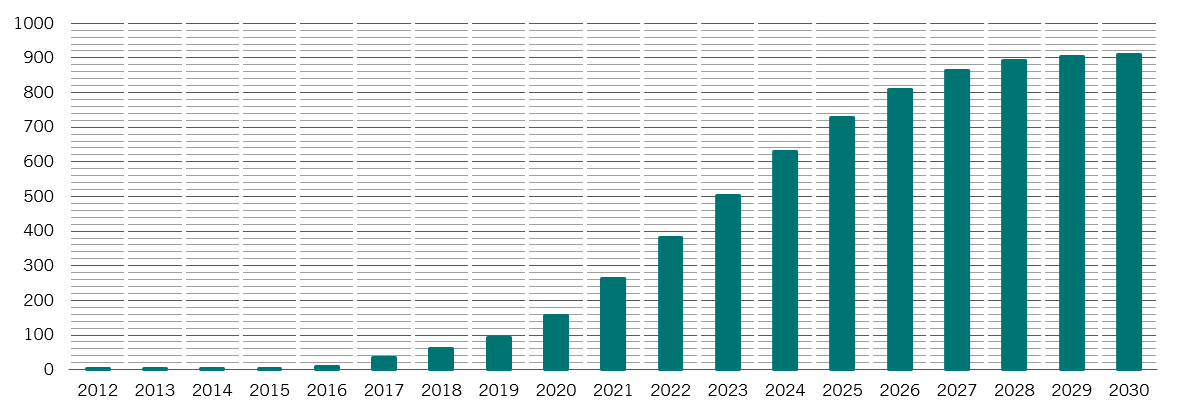

Collaborative robot total annual world sales, '000

Source: Barclays Research. Forecasts from 15.02.2016.

Industrial robots that don't simply follow a limited set of instructions or require a human operator have the potential to liberate skilled workers to focus on more complex tasks. They become even more useful if they can work cooperatively with and in close proximity to those same workers.

For instance, collaborative robots can take assembly line stations, doing fiddly, routine jobs that people dislike, freeing up their human colleagues to work on more value-add tasks like quality control and bespoke modification.

By using off-the-shelf components where possible to complement parts designed in-house, Odense firms can quickly assemble industrial robots with specialist applications and put together complete, working systems that meet clients' needs.

Little wonder, then, that sales of these robot systems are expected to be some 728,000 units - worth USD11.5 billion a year - by 2025. That compares to a market worth just USD800 million in 2017 and one that has grown from virtually a standing start in 2012, according to Barclays Equity Research, with much of the demand coming from the automotive and tech industries.

Doing away with drudgery

As an example, this sort of automation allows workers to be shifted away from routine warehouse work such as material handling. Robots, such as the low, flat pallet movers produced by Mobile Industrial Robots*, another Odense-based company, are increasingly taking over distribution centres. A third firm is working on robotic welding, targeting a large market where there is a declining labour force with the skillset to do the work (in the UK, for example, the average welder is 55 years old).

But it's been a challenge getting to this stage. Collaborative robotics, which is dependent on large amounts of high quality sensor data, has only become possible thanks to the development of increasingly sophisticated sensors as well as advances in computing power to process that data, according to the Advisory Board.

AI is also making it ever easier to train industrial robots. For instance, in some cases, rather than having to be programmed using computer code, robots can be guided through tasks by human operators directly manipulating the robot's arms so that they learn by doing.

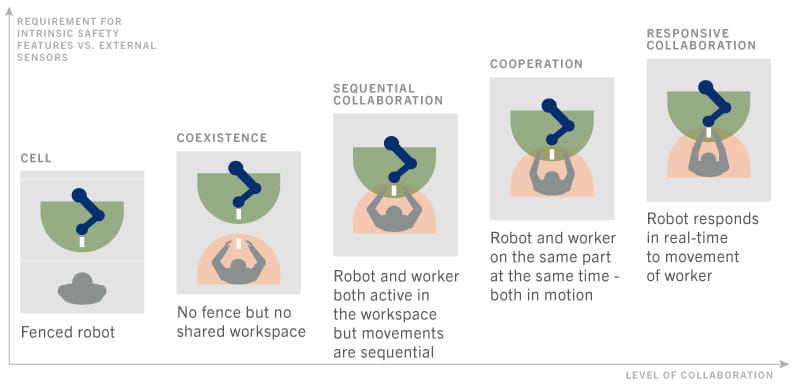

Types of collaboration with industrial robots

Green area: robot's workspace; yellow area: worker's workspace. Source: IRF, based on: Bauer et al. (2016).

Because people aren't robots, safety demands that these autonomous robots need to be able to adapt to variable circumstances. To ensure safety, co-working industrial robots need to be able to be aware of humans in their environment and need to be able to stop or manoeuvre out of the way if there's a risk of injury and then to be able to smoothly return to the task once the danger passes. The latest technology is making that easier.

To ensure that humans remain safe robot manufacturers are bound by standards laid out by the International Organization for Standardization (ISO). Indeed ensuring safety is the most expensive element of this process, which is perhaps why the Chinese government is looking to move away from ISO and to develop its own safety standards. Were China to do so, the risk is that it would trade lower prices for risks to people's safety.

As safety, cost and adaptability are addressed, people will find themselves working ever more with collaborative robots. Robots will increasingly take over some of our tasks, but mainly just dangerous or tedious work, leaving more interesting and varied tasks to humans. What's more, they will increasingly be working side by side.

*The Pictet-Robotics strategy invests in Teradyne which owns both Universal Robots and Mobile Industrial Robots

DISCLOSURES

This marketing material is issued by Pictet Asset Management (Europe) S.A.. It is neither directed to, nor intended for distribution or use by, any person or entity who is a citizen or resident of, or domiciled or located in, any locality, state, country or jurisdiction where such distribution, publication, availability or use would be contrary to law or regulation. Only the latest version of the fund's prospectus, KIID (Key Investor Information Document), regulations, annual and semi-annual reports may be relied upon as the basis for investment decisions. These documents are available on assetmanagement.pictet or at Pictet Asset Management (Europe) S.A., 15, avenue J. F. Kennedy, L-1855 Luxembourg.

The information and data presented in this document are not to be considered as an offer or solicitation to buy, sell or subscribe to any securities or financial instruments.

Information, opinions and estimates contained in this document reflect a judgment at the original date of publication and are subject to change without notice. Pictet Asset Management (Europe) S.A. has not taken any steps to ensure that the securities referred to in this document are suitable for any particular investor and this document is not to be relied upon in substitution for the exercise of independent judgment. Tax treatment depends on the individual circumstances of each investor and may be subject to change in the future. Before making any investment decision, investors are recommended to ascertain if this investment is suitable for them in light of their financial knowledge and experience, investment goals and financial situation, or to obtain specific advice from an industry professional.

The value and income of any of the securities or financial instruments mentioned in this document may fall as well as rise and, as a consequence, investors may receive back less than originally invested. Risk factors are listed in the fund's prospectus and are not intended to be reproduced in full in this document.

Past performance is not a guarantee or a reliable indicator of future performance. Performance data does not include the commissions and fees charged at the time of subscribing for or redeeming shares. This marketing material is not intended to be a substitute for the fund's full documentation or any information which investors should obtain from their financial intermediaries acting in relation to their investment in the fund or funds mentioned in this document.

This document is a marketing communication issued by Pictet Asset Management and is not in scope for any MiFID II/MiFIR requirements specifically related to investment research. This material does not contain sufficient information to support an investment decision and it should not be relied upon by you in evaluating the merits of investing in any products or services offered or distributed by Pictet Asset Management.

This article was a paid posting by Pictet Asset Management all views and/or opinions are those of the sponsor and not of Investment Week.